There are so many options of screw to choose from that often it can be difficult to decide which screw to use for a job. You need to consider screw-head design, screw-thread design, the material of the screw for the subject, and specially designed screws.

Screw-head design

There are three basic screw design options – round, raised and counter-sunk. In general if the screw is being hidden it doesn’t matter which of the three you choose, but if your screw head is exposed you may want to consider a round or raised head. If the work needs a flush finish, the counter-sunk design is optimal.

Screw-thread design

A traditional wood screw has only a single cutting thread covering little over half its overall length. Double-threaded screws are generally designed with a narrower shank that helps avoid splitting as they provide a greater surface area and therefore grip. Double threaded screws are optimal for use with power tools. There are also serrated edged screws where the first part of the screw threads are serrated. This helps the screw cut into the wood and provides a better grip when using lighter materials.

Screw material

Screws are made in many types of material, from brass to zinc-plated, steel to black oxide, and each can be found in the different thread and head designs. To choose the correct screw material you should be guided by what you’re screwing it into, what type of wood it is and the type of structure you’re creating.

Brass screws will not go rusty like steel screws so they will not react with the high tannic acid content of woods such as oak. When working with brass screws you should always drill pilot holes as they tend to overheat and can break. Also beware of ‘brass-plated’ screws – check with a magnet if you’re not sure!

Steel screws are traditionally used for structural work, and ideal for fitting table tops, decking, pergolas – anything that requires strength.

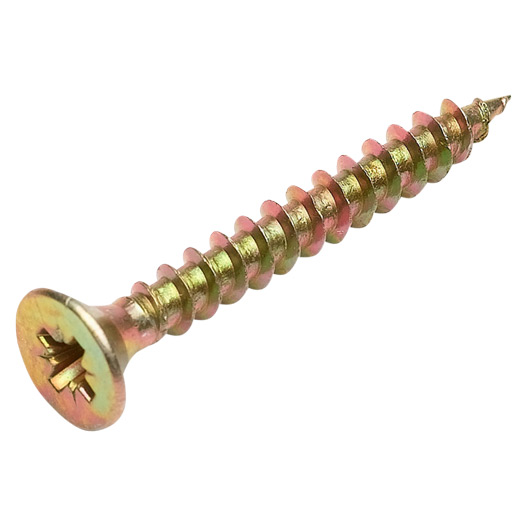

Zinc-plated screws can be driven quickly into both hard and soft woods. They are plated to help prevent corrosion and hardened to stop breakage. In most woods there’s no need for a pilot hole unless working near an end or edge. It’s a great general purpose wood screw.

Black oxide screws are designed specifically for drywalls, for fixing plaster boards. The coating helps reduce corrosion.

There are also screws created specifically for a certain job, such as timber-to-metal screws, security screws (designed to be put in but not taken out) or coach screws which are suitable for tough, outdoor jobs. The essential step in choosing which screw to use is to ensure you know what you’re planning on using it for, what the surface type is you’re drilling it into, and how much strength is needed in the final structure.

We have a huge range of screws available in our online shop.